Energy saving project

saved 491 tons of CO₂ emissions

OSTP works continuously to reduce its environmental impact.

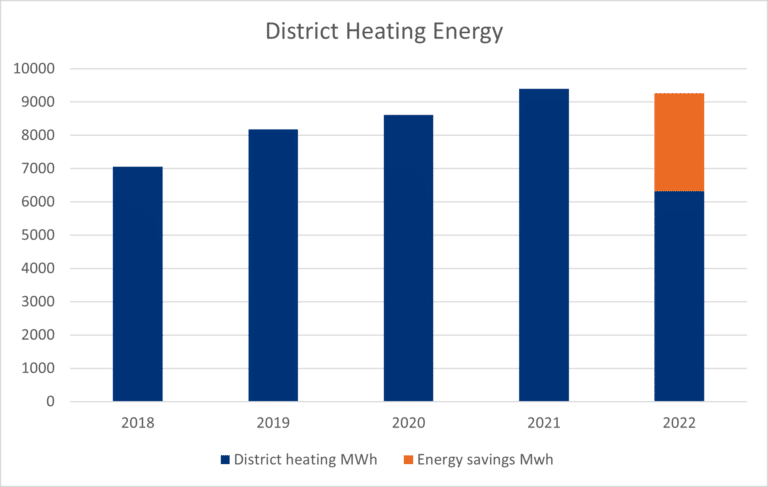

At OSTP’s unit in Jakobstad, the Energy Saving Project #1, which was completed at the end of 2021 and taken into use in 2022, has led to a significant reduction in environmental impact. The installation of heating pumps has saved costs but, above all, reduced the unit’s CO₂ emissions.

Energy savinngs from the production processes

By installing heating pumps, we have managed to achieve yet another goal in OSTP’s Sustainability Roadmap. Thanks to the investment, the energy from the cooling that takes place in the production processes is recovered. When the pumps cool down the water in the process cooling, heat is now transferred both to the process water, but also to heat production facilities,” says Johan Nybacka, Production Manager in Pietarsaari.

Or if you want to compare it to a car, it means 3 382 921 km, a total of 84.4 laps around the globe as the car’s emissions are 145 gr CO₂ / 100 km.

– This was a good project that shows that we have the potential to improve. A really good start in our journey to be CO₂ neutral,” says Jyrki Sironen, who works with the OSTP Group’s sustainability.

A result that adds value

– “We are happy that we managed to achieve the expected result. We have saved a lot of energy, money, and CO₂ emissions by investing in the heating pumps,” says Johan Nybacka.

– “Another important thing is that we got more cooling capacity for process cooling, which is needed especially in the summer,” emphasizes Kimmo Aho, a production technician involved in the project.

– It was a successful project, but the work does not end here, we will now continue to evaluate the rest of the heating and cooling in our processes and see where we can optimize further, Johan Nybacka concludes.

Johan Nybacka, Production Manager, and Kimmo Aho, Production Technician, stand between the heating pumps at the OSTP unit in Jakobstad.